Z Magnet

- Home Page

- Screening Machines

- Z Magnet

Z Magnet

Magnets are the metal, iron, steel, etc. in the product arriving at the raw material entry points. Designed for material extraction. As soon as the raw material in the magnet passes through the magnetic fields, the metals adhere to the magnets and the raw material transition is completed.

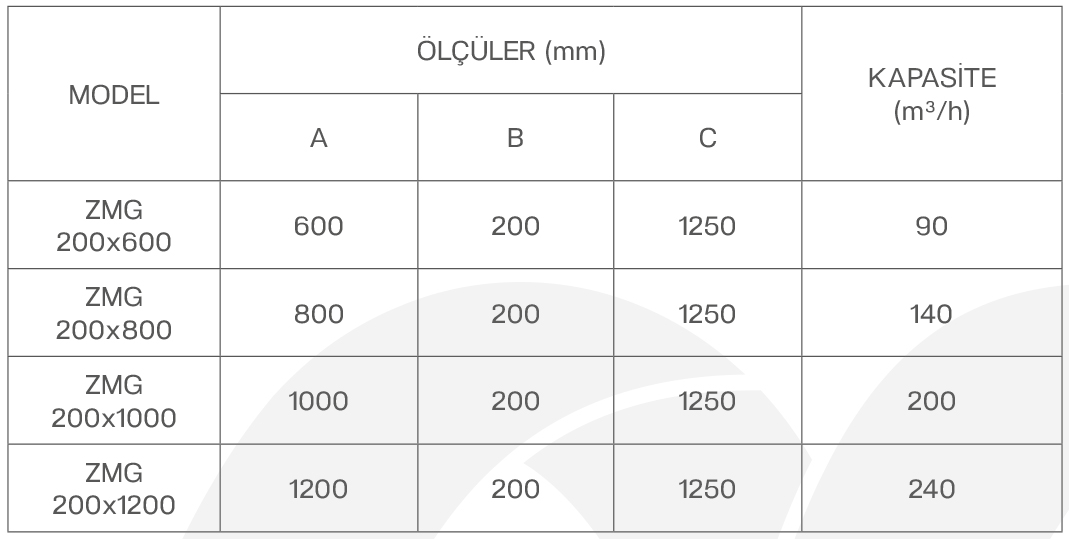

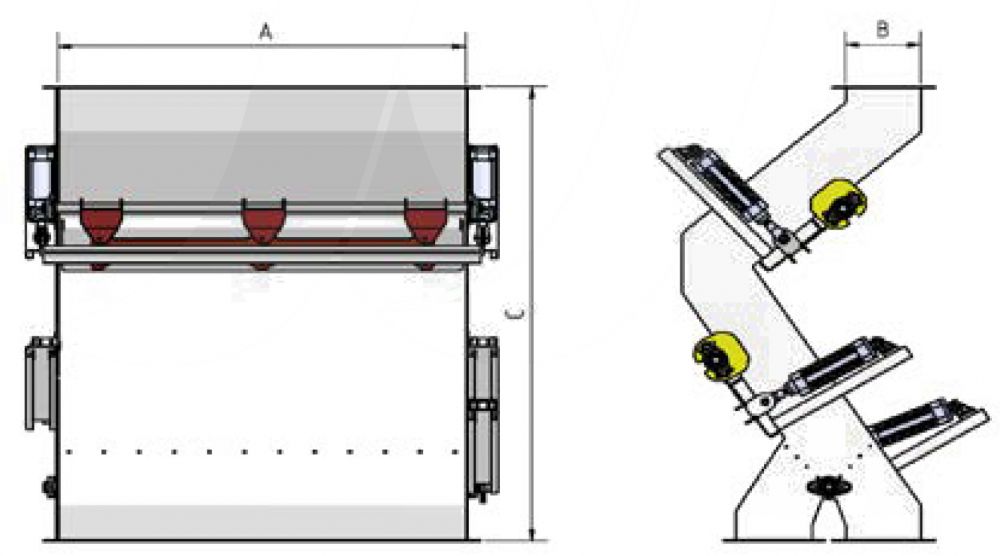

With the gradual method of Z Magnet, the product is checked twice in a single pass. As a result, impurities result in maximum separation. The magnets are protected from external factors by placing them in 304 quality stainless steel. It is a method mostly used for granular and dry material. It is used in chemical, beverage, ceramic, pharmaceutical, plastic plants and sugar, feed, rice factories.

The captured metals are separated from the system by coming together in the metal collection area. There are 3 types of magnets: Y type, Z type and Single layer.

| Features: | Usage Areas : |

| Inspection hatches | It is used in raw material purchasing systems and at certain control points of the units. |

| Lower costs | |

| Ease of maintenance | |

| Automatic metal evacuation feature | |

| Strong pulling power | |

| Easy assembling | |

| Simple parsing | |

| Maximum durability |